- Home

- Products

- Single Facer

- l03-01

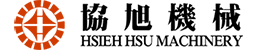

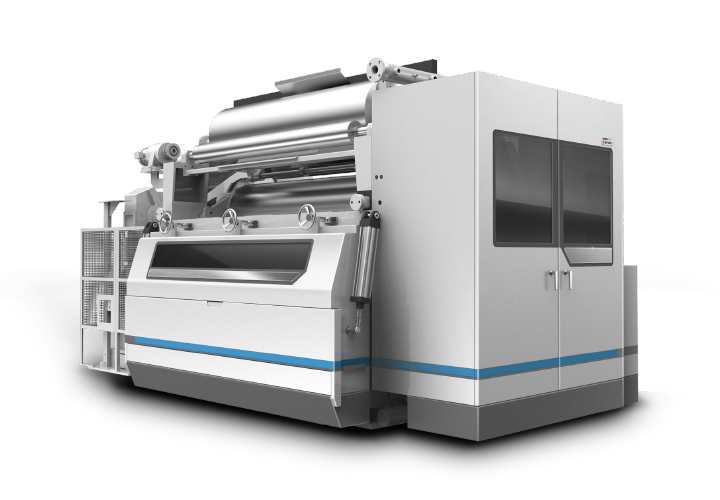

MULTI-CASSETTE POSITIVE PRESSURE SINGLE FACER - MSF-30PA

- Heating type: by steam.(FIG.1, FIG.2)

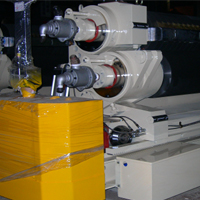

- Types of flute profile: A, B, C, and E profile for option.(FIG.3)

"A-Flute": 35 flutes/300mm, height of flute 4.6mm.

"B-Flute": 48 flutes/300mm, height of flute 2.8mm.

"C-Flute": 40 flutes/300mm, height of flute 3.6mm.

"E-Flute": 88 flutes/300mm, height of flute 1.45mm. - Corrugating roll change system: cassette type, pneumatic motorized.

- Positive press fingerless design for any size of paper production going smoothly.

- Corrugating rolls locate on the base of the machine with the pressure roll being on top of them for lowing down the gravity of the machine and reducing the vibration of the machine to allow the perfect stability at any speed.

- Upper/Lower corrugating rolls: Upper corrugating roll diameter 360mm, Lower corrugating roll diameter 408mm, made of Ni-Cr-Mo (SNCM-439) with heat treatment, hardness over SHORE 75 degree, surface with precise turn ground polish and tungsten carbide treatment.

- Pressure roll: Diameter 450mm, made of (S45C), surface with special heat treatment and turn ground polish.

- Glue roll: Diameter 300mm, steel product, surface sand-blasted and chrome-plated.

- With glue roll auto idle device preventing glue dried on the surface of the glue roll while stopping the machine.(FIG.4)

- Doctor roll: Diameter 180mm, steel product, surface with precise turn ground polish and chrome treatment

- Preheating drum for medium: Diameter 550mm, steel product, rotating synchronously with corrugating rolls.

- Preheating drum for liner : Diameter 550mm, steel product, with brake which can control the tension.

- Glue pan system will offer proper glue film on the surface of the glue roll at any machine speed.

- Glue pan made of stainless steel with a water cooled outer jacket.

- Corrugating rolls and pressure roll bearing housing lubricated by high temperature grease.

- Corrugating rolls, pressure roll and glue roll controlled by hydraulic way.(FIG.5, FIG.6)

- The gap of corrugating rolls, pressure roll and glue roll, doctor roll and lower corrugating roll and glue roll controlled by motorized adjustment device and indicated with digital read out, incorporating a hydraulic motor.(FIG.7)

- Adjustment of the gap between pressure roll and upper corrugating roll, independent on both drive and operation sides.

- With motorized glue dividing device incorporating a AC motor.(FIG. 8)

- With steam rotary joint , stainless steel soft tube and flexible steam piping.

- With 15 HP blower --- 2 sets.(FIG.9)

- With operation panel and control cabinet.

- Motorized cassette carriage: carriage movement operated by battery trolley for forward, backward and stop.

FIG.1

FIG.2

FIG.3

FIG.4

FIG.5

FIG.6

FIG.7

FIG.8

FIG.9